Hello,

this tutorial aims to describe the important parameters of magnetic tapes

It is a translation of a French version (under review); English is not my mother tongue; in a firrst step I will use google translation

to summarize the characteristics of some bands available in 2023 on the market.

There are several reference standards, I only own the IECs and have found partial copies of the NABs.

Reference standards

IEC 60094-6 (1985) Sound recording and playback systems on magnetic tapes - Part 6: Reel-to-reel systems

IEC 60094-2 (1994) Magnetic tape recording and playback systems - Part 2: Standard magnetic tapes

excerpts from 60094-2: any standard master tape must include at least the following sections:

1) reference level;

2) azimuth adjustment;

3) amplitude/frequency response.

Each section should be taped at an angle of 90° ± 1', relative to the edge of the tape.

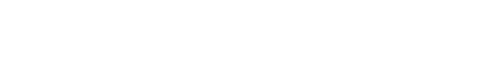

Composition of a magnetic tape

The magnetic tape is made up of different layers as shown in the sketch below

The support material (base, substrate) can be

paper (the very first) stable but fragile

AC cellulose acetate, not stable

PVC, sturdy

PE polyester, polyethylene; stable (not polyester urethane)

the different materials are more or less resistant to the action of time and in particular to humidity.

The tensile force for an elongation of 3% varies according to material, width and thickness; same stress at break.

With all the physical, chemical and magnetic parameters, we can calculate a 'score' for the lifetime of the magnetic tape. Certain makes/models should be avoided. The number of saves/erases has practically no influence. Thus, mentions such as "registered only once" should not be taken into account when purchasing; these are often archival tapes that are good for the trash because chemically/physically damaged and will completely mess up your tape recorder in seconds. The box, the reel may be of interest.

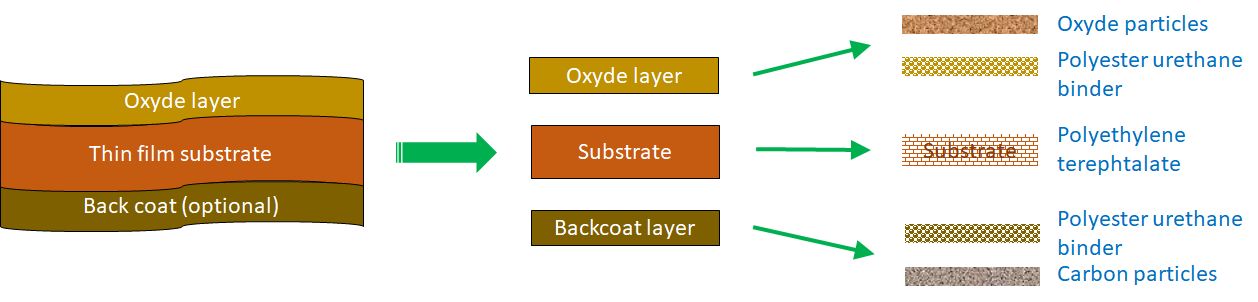

Dimensions and distribution of tracks

Band width:

- CEI 60094-6 (1985) 6.3 mm = 0.248 inch et non 1/4 " (graphe ci-dessous)

- NAB NATIONAL ASSOCIATION OF BROADCASTERS Cartridge "Tape Recording and Reproducing" (1964) 0.246 inch

- NAB E416 (1965) 0.246 ± 0.002

Band Thickness:

there are 4 thicknesses, there are small differences depending on the manufacturer; 'designations' are not standardized

'standard play' 52 µm total thickness

'long play' 35 µm total thickness

'double play' 26 µm total thickness

'triple play' 18 µm total thickness

depending on the thickness, we can put more or less strip [m] on a coil, the thickness of magnetic oxide is independent;

the playing time will vary as in the table below

| Reel Dia | Length | Thickness | [cm/s] | [cm/s] | [cm/s] | [cm/s] | [cm/s] | [cm/s] |

| [cm] | [m] | [µm] | 2.38 | 4.76 | 9.525 | 19.05 | 38.1 | 76.2 |

| 13 | 180 | 52 | 128 | 64.0 | 32.0 | 16.0 | 8.0 | 4.0 |

| 13 | 270 | 35 | 192 | 96.0 | 48.0 | 24.0 | 12.0 | 6.0 |

| 13 | 360 | 26 | 256 | 128.0 | 64.0 | 32.0 | 16.0 | 8.0 |

| 13 | 540 | 18 | 384 | 192.0 | 96.0 | 48.0 | 24.0 | 12.0 |

| 18 | 360 | 52 | 256 | 128.0 | 64.0 | 32.0 | 16.0 | 8.0 |

| 18 | 540 | 35 | 384 | 192.0 | 96.0 | 48.0 | 24.0 | 12.0 |

| 18 | 720 | 26 | 512 | 256.0 | 128.0 | 64.0 | 32.0 | 16.0 |

| 18 | 1080 | 18 | 768 | 384.0 | 192.0 | 96.0 | 48.0 | 24.0 |

| 27 | 760 | 52 | 532 | 266.0 | 133.0 | 66.5 | 33.3 | 16.6 |

| 27 | 1080 | 35 | 768 | 384.0 | 192.0 | 96.0 | 48.0 | 24.0 |

| 27 | 1440 | 26 | 1024 | 512.0 | 256.0 | 128.0 | 64.0 | 32.0 |

| 27 | 2160 | 18 | 1536 | 768.0 | 384.0 | 192.0 | 96.0 | 48.0 |

| 30 | 1100 | 50 | 768 | 384.0 | 192.0 | 96.0 | 48.0 | 24.0 |

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

|

Fabricant

|

modèle

|

année

|

base

|

coating

|

back coating

|

total

|

Pays

|

|

Brand

|

type

|

year

|

[µm]

|

[µm]

|

[µm]

|

[µm]

|

ISO2

|

|

AGFA

|

F

|

1948-

|

16

|

56

|

De

|

||

|

AGFA

|

PEM369

|

1988-1990

|

20

|

11.5

|

1.5

|

33

|

De

|

|

AGFA

|

PE31

|

1958-1968

|

20

|

14.5

|

no

|

35

|

De

|

|

AGFA

|

PE39

|

1986-1990

|

23

|

8

|

--

|

35

|

De

|

|

BASF

|

DP26

|

1996-

|

15.5

|

9

|

1.5

|

26

|

De

|

|

BASF

|

DP26 LH

|

1970-

|

15.5

|

9

|

1.5

|

26

|

De

|

|

BASF

|

DPR26 LH

|

1973-

|

15

|

10

|

1.5

|

29

|

De

|

|

BASF

|

LG/LGN

|

1948-1952

|

30

|

26

|

56

|

De

|

|

|

BASF

|

LP35

|

1970-

|

10

|

35

|

De

|

||

|

BASF

|

LP35 LH

|

1970-

|

10

|

35

|

De

|

||

|

BASF

|

LPR35

|

1996-

|

20

|

11

|

4

|

35

|

De

|

|

BASF/RMG

|

PER528

|

1991-2003

|

30

|

14

|

4

|

48

|

De

|

|

BASF/RMG

|

SM.468

|

1995-2003

|

30

|

14.5

|

48.5

|

De

|

|

|

BASF/RMG

|

SM.900

|

1995-2003

|

30

|

18

|

52

|

De

|

|

|

ATR

|

Master tape

|

-2003-

|

36

|

12.5

|

0.8

|

50

|

US

|

|

ATR

|

MDS-36

|

-2003-

|

24

|

12.5

|

0.8

|

37.5

|

US

|

|

Capture

|

914

|

-2022-2023-

|

36

|

9

|

3

|

48

|

|

|

Capture

|

930

|

-2022-2023-

|

19

|

9

|

3

|

31

|

|

|

Maxell

|

UD18

|

18

|

JP

|

||||

|

Maxell

|

UD25

|

25

|

JP

|

||||

|

Maxell

|

UD35

|

-1979-2002-

|

35

|

JP

|

|||

|

Maxell

|

UD50

|

-1979-

|

50

|

JP

|

|||

|

Quantegy

|

406

|

-2002-

|

35.4 (1.40)

|

10.1

|

0.8

|

46.3

|

US

|

|

Quantegy

|

407

|

-2002-

|

21.5 (0.85)

|

10.1

|

0.8

|

32.4

|

US

|

|

Quantegy

|

456

|

-2002-

|

35.4 (1.4)

|

12.7

|

0.8

|

48.9

|

US

|

|

Quantegy

|

478

|

-2002-

|

35.4 (1.4)

|

15.2

|

0.8

|

52.2

|

US

|

|

Quantegy

|

479 = 478

|

-2002-

|

479-1586LL

|

15.2

|

1/4”x 1650’

|

plastic R 7"

|

US

|

|

Quantegy

|

480

|

-2002-

|

35.4

|

15.2

|

0.8

|

51.4

|

US

|

|

Quantegy

|

499

|

-2002-

|

35.4 (1.4)

|

15.2

|

0.8

|

51.4

|

US

|

|

Quantegy

|

632

|

-2002-2023-

|

36 (1.42)

|

7.9

|

43.9

|

US

|

|

|

Quantegy

|

642

|

-2002-2023-

|

22.4 (0.88)

|

7.8

|

30.2

|

US

|

|

|

Quantegy

|

652

|

-2002-2023-

|

12.2 (0.480)

|

7.8

|

20

|

US

|

|

|

Quantegy

|

661

|

-2022-2023-

|

12.2 (0.480)

|

5.6

|

17.8

|

US

|

|

|

Quantegy

|

795

|

25.3 (1.0)

|

5.1

|

1

|

31.4

|

US

|

|

|

Quantegy

|

GP9

|

-2002-

|

35.4

|

17.7

|

0.8

|

50.9

|

US

|

|

RTM

|

LPR35

|

-2022-2023-

|

20

|

11

|

35.5

|

Fr

|

|

|

RTM

|

LPR90

|

-2022-2023-

|

20

|

12

|

35.5

|

Fr

|

|

|

RTM

|

SM468

|

-2022-2023-

|

30

|

14.5

|

48.5

|

Fr

|

|

|

RTM

|

SM.900

|

-2022-2023-

|

30

|

19

|

52

|

Fr

|

|

|

RTM

|

SM911

|

-2022-2023-

|

30

|

16

|

50

|

Fr

|

|

|

Scotch 3M

|

111

|

1948-

|

38.1

|

17.8

|

55.9

|

US

|

|

|

Scotch 3M

|

206 (21)

|

1979-

|

15.2

|

5.6

|

20.8

|

UK

|

|

|

Scotch 3M

|

206 (50)

|

1969-1979-

|

36.1

|

14.2

|

52.8

|

US

|

|

|

Scotch 3M

|

207 (15)

|

1979-

|

9.5

|

5.6

|

15.1

|

UK

|

|

|

Scotch 3M

|

207 (35)

|

1969-1979-

|

21.6

|

14.2

|

38.4

|

US

|

|

|

Scotch 3M

|

250

|

1979-

|

33

|

16.5

|

2

|

51.5

|

UK

|

|

Scotch 3M

|

256

|

1979-

|

33

|

17

|

3

|

53

|

UK

|

|

Scotch 3M

|

265

|

1979-

|

20

|

3.8

|

2.5

|

26.3

|

UK

|

|

Scotch 3M

|

806

|

1986-

|

36.1

|

10.2

|

48.3

|

US

|

|

|

Scotch 3M

|

807

|

1986-

|

23.4

|

10.2

|

35.6

|

US

|

|

|

Scotch 3M

|

908

|

1993-

|

35.1

|

9.1

|

46.2

|

US

|

Note (year) put on the market: '1948-' beginning; '-1995' end; '-1979-' or '-2001-2023-' seen in a magazine, a site that (these) year(s) there

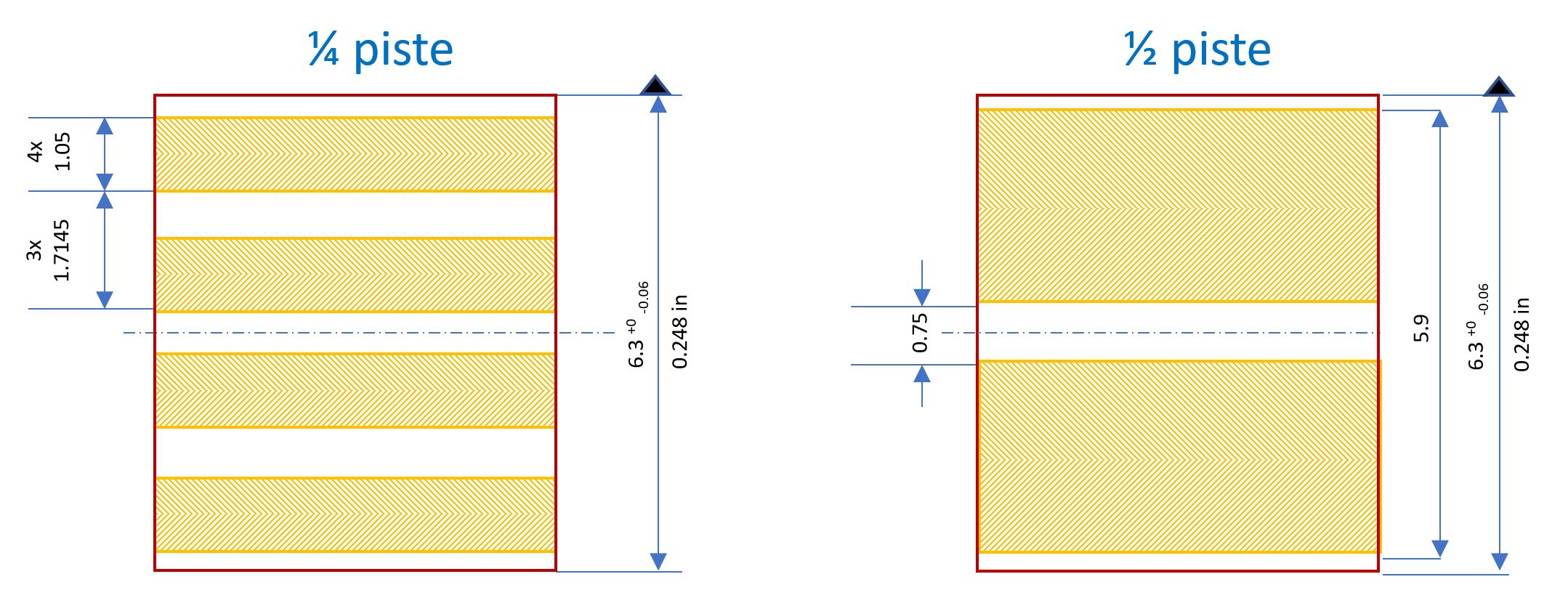

Magnetic characteristics

Bias (recording and playback)

It seems to me necessary here to give some explanations on the magnetic properties of a tape, their composition and details on the heads of recording and reading. In addition, it is necessary to take a look at the principle of AC polarization (tutorial on AF)

The main magnetic quantities used are:

Magnetic flux (unit: Wb)

Flux density B (unit: T) = 10,000 Gauss

Magnetic field strength H (unit: A/m)

They are linked by the equations: B = µ x H [1 x A/m]; Φ = B x S [T x m²]

The saturation flux density of professional tapes is < 100 mT

A typical value for the maximum value of the flux density recorded in the emulsion of a magnetic tape is 50 mT. This would be achieved at the maximum value of a full record level record.

Calculation 1

The effective value of this flux density is then

Brms=0.71*50mT=35mT

The total flux in the ribbon emulsion is then the product of the flux density and the magnetic surface area. This surface is the product of the width of the tape and the thickness of the emulsion.

S=6.3mm*14μm=9*10-8m²

Φrms = 35 mT * 9 * 10-8 m² = 3150 pWb

This total flux in the emulsion is normally related to the track width. Therefore, we state it in terms of flux per mm of track width: Φrms/width = 3150 pWb / 6.3 mm = 500 pWb / mm = 500 nWb / m

It's a bit unusual for me to see Wb/m, we can see in the detail above that it's the right unit (you can replace the 6.3 mm by the magnetic width of 1.05 mm in the case of 4 tracks , the value is the same)

This is a typical value for the flux level used in modern tape recording (professional equipment) in yellow in the tables below

| Ref fluxivity cal tape [nWb/m] | desired ref Fluxivity [nWb/m] | |||||

|

1 kHz (700Hz)

|

185

|

200

|

250

|

G.320

|

355

|

500

|

| 180 (185) | 0.00 dB | -1.00 dB | -3.00 dB | -4.00 dB | -6.00 dB | -9.00 dB |

| 200 | 1.00 dB | 0.00 dB | -2.00 dB | -3.00 dB | -5.00 dB | -8.00 dB |

| 250 (260) | 3.00 dB | 2.00 dB | 0.00 dB | -1.00 dB | -3.00 dB | -6.00 dB |

| 320 | 4.00 dB | 3.00 dB | 1.00 dB | 0.00 dB | -2.00 dB | -5.00 dB |

| 355 (370) | 6.00 dB | 5.00 dB | 3.00 dB | 2.00 dB | 0.00 dB | -3.00 dB |

| 500 | 9.00 dB | 8.00 dB | 6.00 dB | 5.00 dB | 3.00 dB | 0.00 dB |

- 3M data induction 50-150 mT

- below fluxivity values found in the literature (column 1), tape datasheet or on the net (forum)

- knowing that the signal current is about 3 to 20% (here 14.6 & 21%) of the bias signal, based on "calculation 1" we can make an estimate of column 2-3-4 (each manufacturer has decided based on SN ratio, THD etc)

we take the coating thicknesses in the table above

|

Fabricant

|

modèle

|

Hc coercivity

|

Brms

|

Saturation flux

|

Fluxivity

|

Fluxivity

|

Fluxivity

|

Fluxivity

|

|

Brand

|

type

|

[kA/m (Oe)]

|

[mT]

|

[nWb/m]

|

[nWb/m]

|

[nWb/m]

|

14.6%

|

21%

|

|

AGFA

|

F

|

6.8

|

34

|

540

|

(79) 112

|

79

|

112

|

|

|

AGFA

|

PEM369

|

27.2

|

115

|

1350

|

(193) 272

|

193

|

272

|

|

|

AGFA

|

PE31

|

23.5

|

95

|

1380

|

(201) 284

|

201

|

284

|

|

|

AGFA

|

PE39

|

27.2

|

135

|

1080

|

(158) 222

|

158

|

222

|

|

|

BASF

|

DP26

|

26 (325)

|

145

|

1300

|

250-320

|

(191) 269

|

191

|

269

|

|

BASF

|

DP26 LH

|

(310)

|

110

|

1100

|

250

|

(145) 204

|

145

|

204

|

|

BASF

|

DPR26 LH

|

(310)

|

120

|

1200

|

320

|

(175) 247

|

175

|

247

|

|

BASF

|

LG/LGN

|

6.4

|

26

|

--

|

(99) 139

|

99

|

139

|

|

|

BASF

|

LP35

|

(300)

|

90

|

250

|

(131) 185

|

131

|

185

|

|

|

BASF

|

LP35 LH

|

(310)

|

110

|

250

|

(161) 227

|

161

|

227

|

|

|

BASF

|

LPR35

|

25

|

165

|

1800

|

(265) 374

|

265

|

374

|

|

|

BASF/RMG

|

PER528

|

137

|

1920

|

(280) 395

|

280

|

395

|

||

|

BASF/RMG

|

SM.468

|

30

|

140

|

1990

|

320

|

(296) 418

|

296

|

418

|

|

BASF/RMG

|

SM.900

|

28.6

|

134

|

2410

|

(352) 497

|

352

|

497

|

|

|

ATR

|

Master tape

|

26.3

|

140

|

320

|

(256) 361

|

256

|

361

|

|

|

ATR

|

MDS-36

|

26.3

|

140

|

320

|

(256) 361

|

256

|

361

|

|

|

Capture

|

914

|

(360)

|

130

|

1950

|

(171) 241

|

171

|

241

|

|

|

Capture

|

930

|

(360)

|

130

|

1950

|

(171) 241

|

171

|

241

|

|

|

Maxell

|

UD18

|

200

|

(0) 0

|

0

|

0

|

|||

|

Maxell

|

UD25

|

(0) 0

|

0

|

0

|

||||

|

Maxell

|

UD35

|

(0) 0

|

0

|

0

|

||||

|

Maxell

|

UD50

|

(0) 0

|

0

|

0

|

||||

|

Quantegy

|

406

|

26.3 (330)

|

130

|

1400

|

(200) 250

|

(192) 270

|

192

|

270

|

|

Quantegy

|

407

|

26.3 (330)

|

130

|

--

|

(192) 270

|

192

|

270

|

|

|

Quantegy

|

456

|

25.5 (320)

|

150

|

2300

|

(250) 355

|

(278) 392

|

278

|

392

|

|

Quantegy

|

478

|

29.5 (370)

|

140

|

--

|

(311) 438

|

311

|

438

|

|

|

Quantegy

|

479

|

29.5 (370)

|

140

|

--

|

(311) 438

|

311

|

438

|

|

|

Quantegy

|

480

|

29.5 (370)

|

140

|

(311) 438

|

311

|

438

|

||

|

Quantegy

|

499

|

31.1 (390)

|

160

|

2900

|

(355) 500

|

(355) 501

|

355

|

501

|

|

Quantegy

|

632

|

24.7 (310)

|

110

|

--

|

(127) 179

|

127

|

179

|

|

|

Quantegy

|

642

|

24.7 (310)

|

110

|

1000

|

(--) 200

|

(125) 177

|

125

|

177

|

|

Quantegy

|

652

|

24.7 (310)

|

110

|

--

|

(125) 177

|

125

|

177

|

|

|

Quantegy

|

661

|

24.7 (310)

|

110

|

--

|

(90) 127

|

90

|

127

|

|

|

Quantegy

|

795

|

27.5 (345)

|

100

|

--

|

(74) 105

|

74

|

105

|

|

|

Quantegy

|

GP9

|

29.5 (370)

|

160

|

413

|

583

|

|||

|

RTM

|

LPR35

|

25.5 (320)

|

127

|

1800

|

(204) 288

|

204

|

288

|

|

|

RTM

|

LPR90

|

29.5 (370)

|

158

|

2400 ?

|

320

|

(277) 391

|

277

|

391

|

|

RTM

|

SM468

|

30

|

140

|

1990

|

320

|

(296) 418

|

296

|

418

|

|

RTM

|

SM.900

|

29.5 (370)

|

154

|

2319

|

320

|

(427) 603

|

427

|

603

|

|

RTM

|

SM911

|

25.5 (320)

|

145

|

2320

|

320

|

(339) 478

|

339

|

478

|

|

Scotch 3M

|

111

|

21.6

|

90

|

1024

|

(--) 200

|

(234) 330

|

234

|

330

|

|

Scotch 3M

|

206 (21)

|

25.6

|

105

|

1488

|

(200) 250

|

(86) 121

|

86

|

121

|

|

Scotch 3M

|

206 (50)

|

25.6

|

105

|

1488

|

(200) 250

|

(218) 307

|

218

|

307

|

|

Scotch 3M

|

207 (15)

|

25.6

|

105

|

1488

|

(200) 250

|

(86) 121

|

86

|

121

|

|

Scotch 3M

|

207 (35)

|

25.6

|

105

|

1488

|

(200) 250

|

(218) 307

|

218

|

307

|

|

Scotch 3M

|

250

|

30.2 (380)

|

120

|

(289) 408

|

289

|

408

|

||

|

Scotch 3M

|

256

|

30.2 (380)

|

100

|

1050

|

(320)

|

(248) 350

|

248

|

350

|

|

Scotch 3M

|

265

|

(700)

|

135

|

(75) 106

|

75

|

106

|

||

|

Scotch 3M

|

806

|

29.6

|

140

|

1440

|

(208) 294

|

208

|

294

|

|

|

Scotch 3M

|

807

|

29.6

|

140

|

1440

|

(208) 294

|

208

|

294

|

|

|

Scotch 3M

|

908

|

29.2

|

160

|

1440

|

(213) 300

|

213

|

300

|

example with Quantegy 499 (I did not put the intermediate calculations)

Recording and tape head modeling attempt

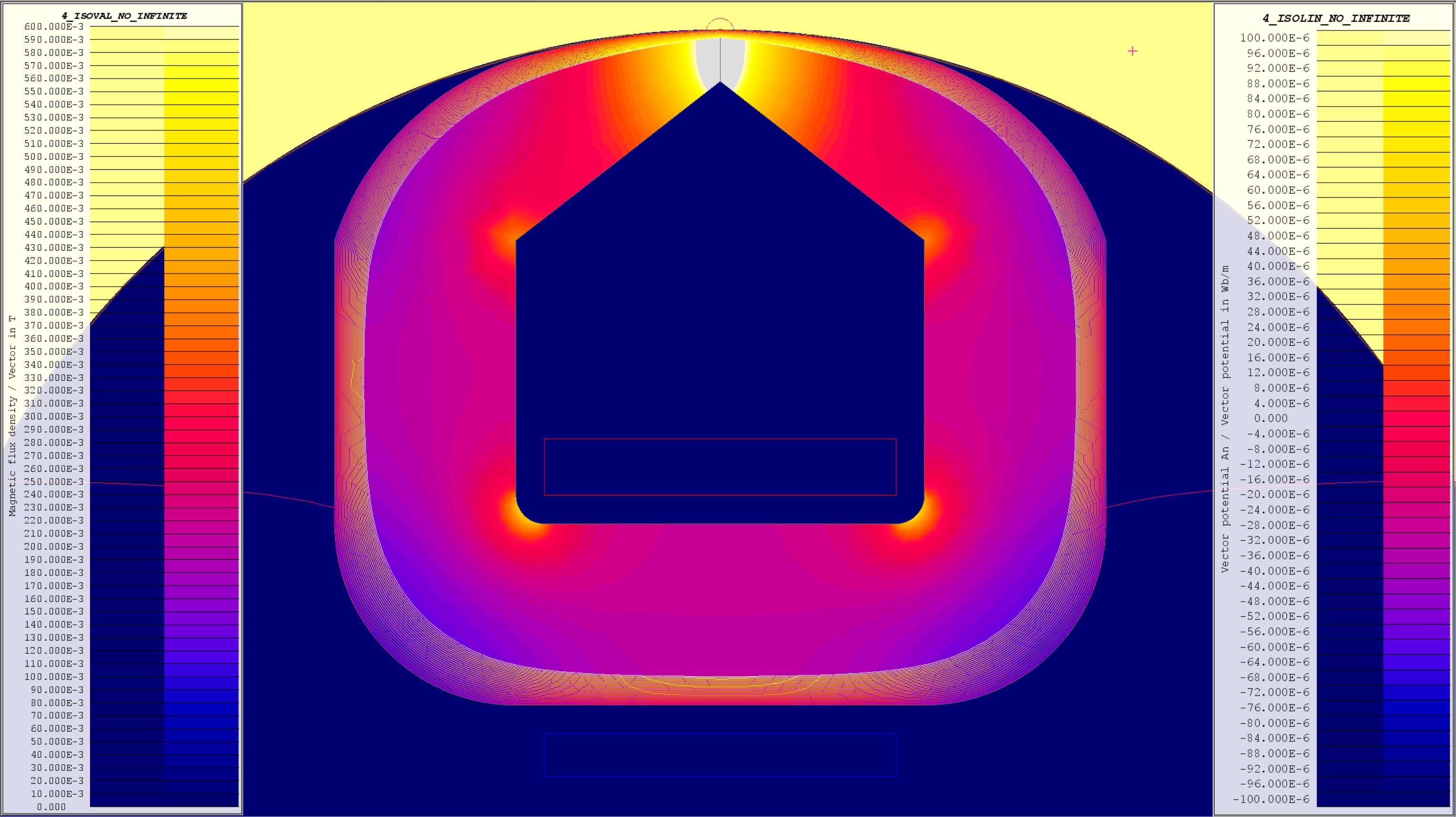

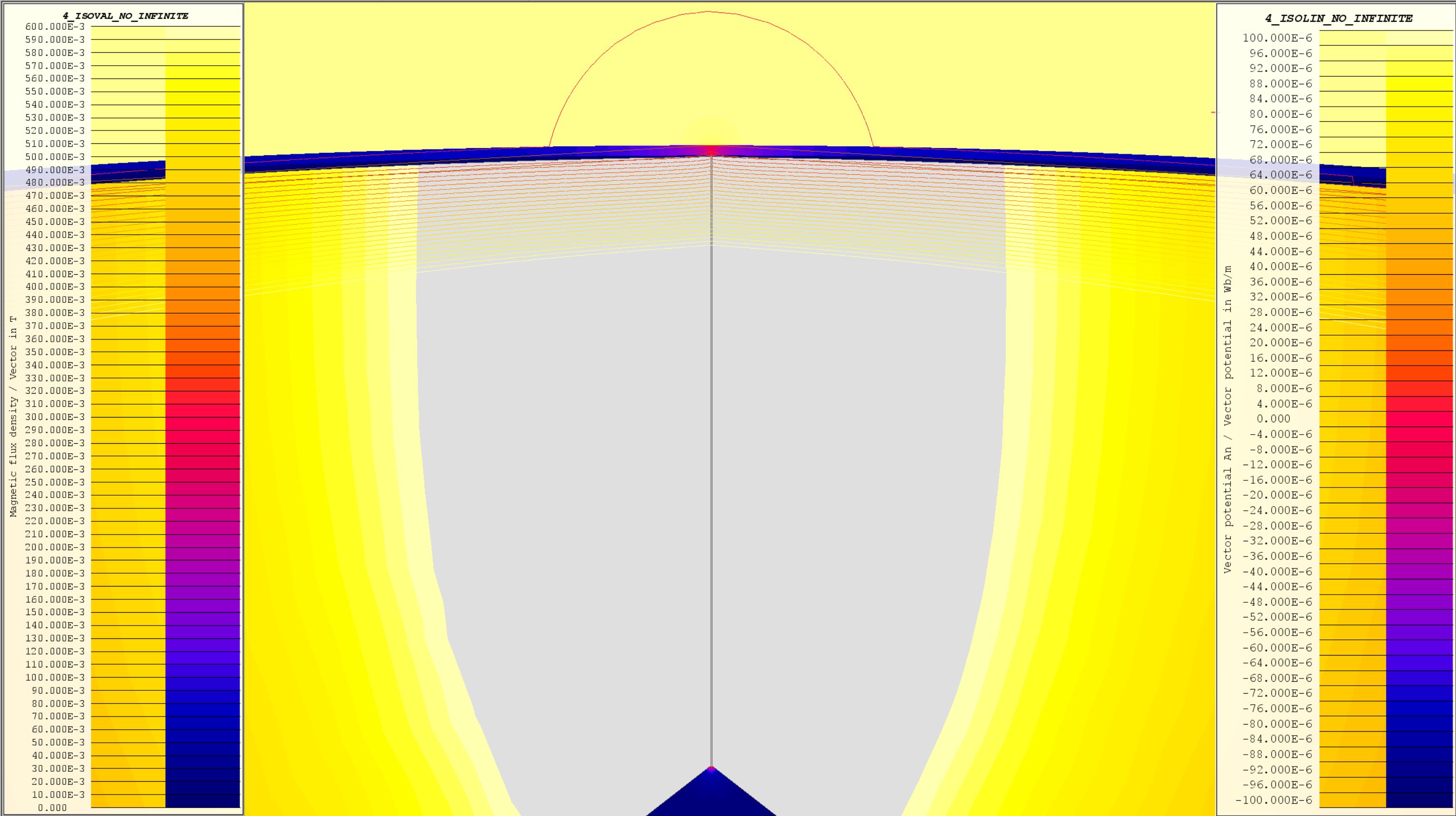

the first simulations of the recording give the following results, some parameters are guessed and to be confirmed. I use a model with kinematics, the tape is a 50 µm ring that rotates anti-clockwise (you only see the top). The material is a "magnet" with the data of the manufacturer of the SM 911 (used in this tutorial) then of SM 900 & LPR 35

the highest induction [T] in the band (at the location of the air gap) is higher than indicated above (0.15T) but when the material saturates, the induction increases further if H [ A/m] increases. In the head, it is weak ± 100 mT

References:

- TEAC "A-3440 service manual"

- MAGNETIC REFERENCE LABORATORY, INC Choosing and Using MRL "Calibration Tapes for Audio Tape Recorder Standardization"

- Masanori Kimizuka "Historical Development of Magnetic Recording and Tape Recorder"

- JRF Magnetic Sciences: "Tape Heads-An Introduction"

- NAB MAGNETIC TAPE RECORDING AND REPRODUCING STANDARDS REEL-TO-REEL

- NATIONAL ASSOCIATION OF BROADCASTERS "NAB Standard Cartridge tape recording & reproducing"

- JOHN G. McKNIGHT "Speed, Pitch, and Timing Errors in Tape Recording and Reproducing"

- ROBERT K. MORRISON FOUNDER STANDARD TAPE LABORATORY "STANDARD TAPE MANUAL"

- IEC 60094-6 (1985) Magnetic tape sound recording and reproducing systems. Part 6: Reel to reel systems

- SCOTCH Magnetic Tape "Sound Talk" vol1 #2 (1968) High frequency bias requirements for magnetic tape recordings

- HP (1967) rev1975 Magnetic tape recording handbook HP-AN-89

- NASA (1982) ref 1075 Magnetic Tape Recording for the Eighties