-beginning of writing 26/11/2022-

The lubrication of tape recorders is a seemingly simple subject, but if you want to extend the life of the devices and space out maintenance, you have to choose the right oil or grease. Tis tutorial ia a translation of a French version under review. In a first step I will use google to translate

The oils

The easiest way is to choose the oil recommended by the manufacturer (in yellow), which is very expensive and may only be suitable for certain models/brands. In addition, different oils are needed depending on the part to be lubricated.

Browsing through a few forums and doing some research, I've compiled the info in the following table.

Personally (in green) for the capstans, I use a motor oil of medium viscosity but very stable in temperature, much less expensive, I use a motor oil of very high viscosity index. For the various wheels and wheels as well as for the levers, a fairly fluid hydraulic oil. It's up to you to see if it suits your device and the materials (ferrous metals, Cu and alloys, plastics) that make it up.

It is essential to clean off all traces of the old lubricant which may not be of the same nature and which may not be compatible with the new one; we can for example put in excess to "drive out" the old lubricant and then remove the excess.

|

Reference

|

Viscosity 40°

[mm²/s]

|

Viscosity 100°

[mm²/s]

|

Viscosity index

ASTM 2270

|

Reference, type

Used by

|

| sensitivity T° | ||||

| ISO VG10 | 10 | * | * | SINGER -H sewing machine- |

| AL Sew-1-2/00 | 13 | 3.2 | 121 | |

| TS619 | 18 | 4 | 120 | |

| AZOLLA ZS | 22 | 4.4 | 102 | hydraulic ISO 22 |

| AZOLLA ZS | 32 | 5.4 | 102 | hydraulic ISO 32 |

| AZOLLA ZS | 46 | 6.8 | 100 | hydraulic ISO 46 |

| AZOLLA ZS | 68 | 8.7 | 100 | hydraulic ISO 68 |

| ISOFLEX PDP 65 | 68 | 16 | 251.6 | STUDER, REVOX, NAGRA |

| ANDREOL 456 | 34 | 7.9 | 228 | NAKAMICHI OTARI |

| KANTO KASEI Floil sintered bearing |

* | * | 230 | SONY |

|

AMPEX 087-579

[Mobile DTE 25]

|

[44.5]

|

[6.9]

|

[98]

|

OTARI MX-5050

2s 4s 2sd 4sd [hydraulic ISO 46]

|

|

ESSO Teresso 43

[Mobil DTE 24]

|

[31.5] | [5.3] |

[98]

|

Revox A36

[hydraulic ISO 32]

|

| CASTROL heavy duty ATF | 36 (34) | 7.2 (7.7) | 175 (210) | -automatic transmission- |

| MOBIL ATF SHC | 33 | 7.4 | 200 | |

| MOBIL ATF 320 | 35 | 7.7 | 201 | |

| MOBIL 10W20 | 44.8 | 8.7 | 173 | -engine- |

| MOBIL 10W30 | 56 | 10.3 | 175 | -engine- |

| CASTROL EDGE 0W30 | 72 | 12.3 | 170 | -engine- |

| CASTROL EDGE 0W40 | 76 | 12.8 | 171 | -engine- |

| MANNOL Hypoid GL 80W/90 | 159.6 | 16.3 | 107 | compatible with Cu and alloys |

| MOTOREX gear oil hypoid SAE 80W/90 | 141.9 | 15.1 | 107 | compatible with Cu and alloys |

| PAG 100 | 100 | 19 |

212

|

-climatiser-

ok R134A et R1234yf

not compatible with other types |

| XENUM XPG 5W50 | 109 | 17.7 | 180 | |

|

SPHERETECH GREEN OIL SAE 5W-50

(10W60)

|

94.5

|

18.2

|

213

|

-engine-

29€/L 11/2022

compatible same grade

|

|

LIQUI MOLY

|

168

|

24

|

175

|

-engine- |

|

CASTROL Edge 10W-60

|

160

|

22.7

|

173

|

-engine- |

Note: equivalent reference and values in [brackets] I could find

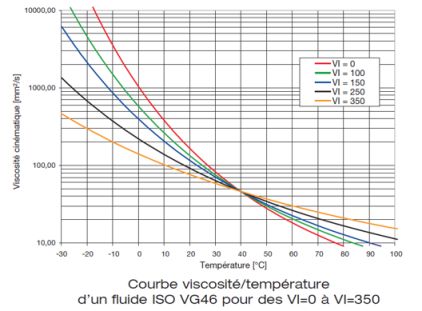

example of viscosity variation as a function of viscosity index

Grease (to come)