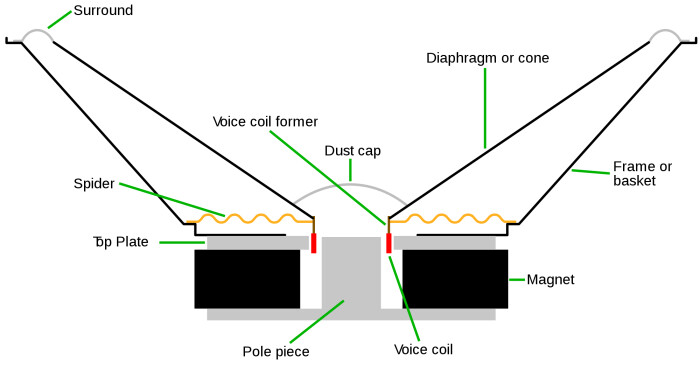

We started this series by describing the cone diaphragm of an electrodynamic speaker. It obviously plays an important role in the final quality of a speaker, as the radiating element, but it's far from being the only spot where signal can be degraded. Today I'll address the importance of the suspensions and magnets.

Peripheral suspension

The frame of the speaker is fixed with a surround which can be more or less flexible, called suspension. Its primary function is to keep the diaphragm in place while providing it enough room for movement. And it also plays a role in preventing the displacement of the diaphragm and absorbing ensuing resonances. The peripheral suspensions can have multiple profiles and materials. The earliest models were made of chamois leather, fabric or paper. But they were gradually replaced with rubber and synthetic foams. The suspension and diaphragm can also be made one single piece by applying a special treatment to the external frame of the latter, using special molding and varnishing techniques.

The material of the suspension must be chosen according to the density of the diaphragm and the frequency range of the speaker; it must allow the required displacement in this range while remaining as neutral as possible. However, the most neutral materials aren’t necessarily the most rigid and it’s not unusual for the suspension to degrade before the diaphragm. So manufacturers must once again make a compromise given the contradictions of having enough flexibility, acoustic neutrality, a long-lasting and quality performance…

Spider

The suspension is not enough to keep the mobile parts (voice coil and diaphragm) of the speaker in place. If you want the movement to be in one single axis, in other words prevent any movement that produces non-linear distortion, it’s necessary to have something to keep the voice coil in place. The distance from the voice coil to the magnet must always be the same and it should never come in touch with it, despite the narrowness (a couple of millimeters) of the air gap between the pole pieces where the coil sits.

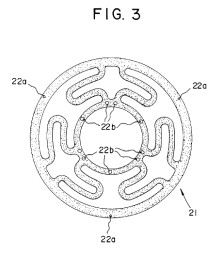

This suspension generally takes the form of a disk which is fixed to the support of the voice coil on one side and to the frame on the other. This element gets its name from its round shape and leg-like design resembling a spider, although currently most speaker spiders don’t really look like a real spider anymore. They are made of a fabric impregnated with a stiffening resin and often have a corrugated shape which favors a controlled damping. Spiders must be manufactured with utmost care in order to not encourage movement in any one direction and to provide a homogeneous movement of the voice coil. A trade-off must be made between a good rigidity that guarantees keeping the voice coil in place, and a great flexibility which allows it to move easily.

Magnetic circuit

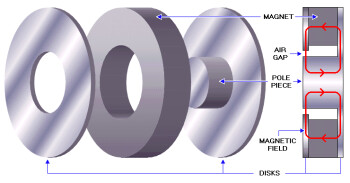

The intensity of the magnetic field in which the voice coil moves is key to the sensitivity of the speaker. The quality of the magnetic field depends on the characteristics of the magnet and a good assembly of the pole pieces. These pieces are made of soft iron or an easily magnetized material. They are used to place the poles of the magnet in front of each other, at the same level as the air gap, leaving just enough space for the voice coil to move within the magnetic field. The narrower the gap the stronger the magnetic field, but the lees room the voice coil will have to dissipate the accumulated heat.

The magnets can be made of several materials. Manufacturers choose them according to their intrinsic qualities. They must consider the intensity of the magnetic field, the space available, how their magnetic qualities hold in time and under extreme conditions, and especially the production costs. Ever since the prices of cobalt started soaring in the 1970s it has been replaced more and more with ferrite and neodymium alloys.

Depending on the type of magnet and the size of the speaker, the magnet can be mounted at the center of the voice coil or at the edges, around the voice coil. The center-mounting technique guarantees less magnetic leaks, but it makes it harder to cool down the voice coil (the magnet is pierced so that air can flow through it). This type of mounting favors cobalt magnets, which partially explains the current predominance of peripheral mounting, which is more adequate for ferrite and neodymium magnets.

After this brief review (which was by no means meant to be exhaustive!) of some of the most important issues affecting the design of electrodynamic cone loudspeakers, in the next article we’ll discuss dome and compression chamber loudspeakers.