Sound is possible thanks to transduction, in other words, the transformation from one form of energy into another one.

Contrary to a microphone, a speaker transforms electric energy into acoustic energy. Sound reproduction has always been an open field for experimenting with different transduction techniques, with differing degrees of success. Before the era of the moving-coil speakers, from 1876 (when Alexander G. Bell patented the first electroacoustic transducer) to 1925, the usual way to reproduce sound was with horn drivers (telephone, phonograph) rather than with loudspeakers strictly speaking. Without amplification (the triode wouldn’t be invented until 1906), developing a device that allowed several people to listen to the same signal at the same time was pretty much impossible. Some models already featured modern loudspeakers, but it wasn’t until the '20s when the amplifier was integrated into the speakers when it became finally possible to fill an entire room with sound.

History and operation

![Radiola104[radiolaguy.com] Radiola104[radiolaguy.com]](https://medias.audiofanzine.com/img/pictures/normal/1/4/1405392.jpg?fm=pjpg&w=350&h=255&fit=contain&s=9ca0e0d2a378104aeecf6efa0834a509)

In 1925 a model of loudspeaker developed by engineers Rice and Kellogg (who have nothing to do with the cereal!) was introduced. Both the speaker itself and its enclosure represented a real breakthrough, incorporating a field coil, a cone diaphragm and suspensions. The built-in amplifier guaranteed enough power to drive the speaker and surely contributed to the commercial success of the model, providing unprecedented listening comfort. Even if the goal wasn’t to achieve the perfect frequency response form 20Hz to 20kHz (producing a sound that was as “natural” as possible was good enough), it featured all main components of a loudspeaker. And, despite all later developments, its creators wouldn’t be shocked by modern speakers.

The family of moving-coil speakers ranges greatly in size and form, but at the core of them all is a wire wrapped around a cylinder and placed inside the magnetic field of a magnet. The interaction between the magnet and the voice coil through which the signal from the amp passes makes the coil move. The latter moves back and forth depending on the oscillation of the signal (so you could say that the transduction is electro-mechanic-acoustic, if you want to be more precise).

![Loudspeaker bass [Svjo CC BY SA 3.0] Loudspeaker bass [Svjo CC BY SA 3.0]](https://medias.audiofanzine.com/img/pictures/normal/1/4/1405391.png?fm=pjpg&w=350&h=255&fit=contain&s=7f20f0585c808edac30577699e7cef2e)

Cone diaphragm

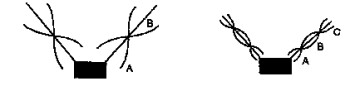

A compromise between rigidity and lightness is necessary to allow the diaphragm to move as uniformly as possible. The diaphragm ought to be rigid enough (and have a tendency to being heavy) to behave as a piston but, at the same time, it ought to be light enough to allow for a good reproduction of transients. The angle of the cone itself requires another trade-off as well: the narrower, the better for the rigidity, at the expense of a wider directivity; the wider the angle, the faster it stops behaving as a piston, but the directivity is higher.

The parameters affecting the end result are many. From the user’s point of view, the first thing you notice is the diameter of the speaker, which determines the frequency range it will be able to reproduce best. Broadly speaking, larger diameters provide more power in the low end, but aren’t as fast as small diameter cones to be able to correctly reproduce highs.

In practice, a cone diaphragm stops behaving as a piston at the frequencies where its own vibration modes are excited. The part of the diaphragm closest to the center actually separates from the outermost part. This results in resonances and other anomalies in the speaker’s response. Which is yet another argument for filtering the signal and having different diameters depending on the frequency band you wish to reproduce.

Research in the field of diaphragms has led to many different variations to try to achieve the best response and/or the best efficiency possible: paper or vegetable fibers, metal, kevlar and other synthetic materials, carbon fiber, blends, and composites. Manufacturing techniques have also improved: thermoforming and injection molding allow sculpting ribs into the diaphragm to make it more rigid and to create sophisticated honeycomb or sandwich constructions. At the same time, the tools have become ever more precise, making it possible to improve the modeling and reduce the defects.

In the next article we’ll keep on describing the components of a moving-coil speaker, focusing on suspensions and the magnetic circuit.